Common Challenges vs. Business Objectives

The Challenge

The Objective

Unexpected machine downtime

Maximize asset utilization

Material shortages halting production

Improve on-time delivery

Constant rescheduling due to rush orders

Increase agility

Lack of visibility into work orders

Enhance shop floor productivity

Manual tracking of rework

Reduce scrap costs

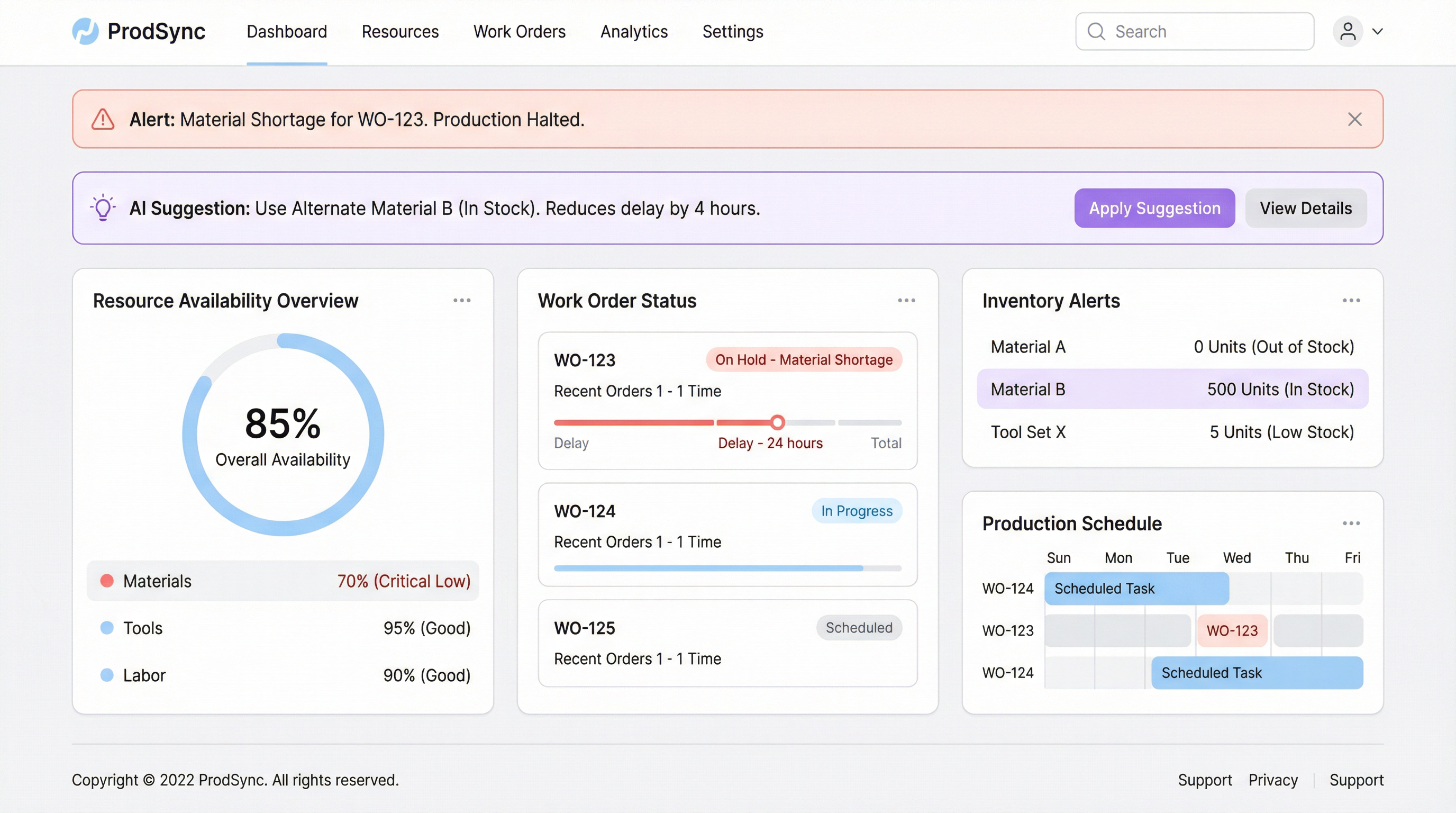

RESOURCE AVAILABILITY: No More Stoppages

"Work order released, but material isn't there. Machine sits idle, schedule collapses."

Before (Manual)

- • Operator finds material missing

- • Informs supervisor -> store -> planner

- • Planner scrambles for alternate

- • Machine idle for 4 hours

Result: Lost capacity & missed delivery

With ProssimaAI

- Proactive Feasibility Checks

- Predictive Shortage Alerts

- Intelligent Alternate Suggestions

Result: Smooth, uninterrupted flow

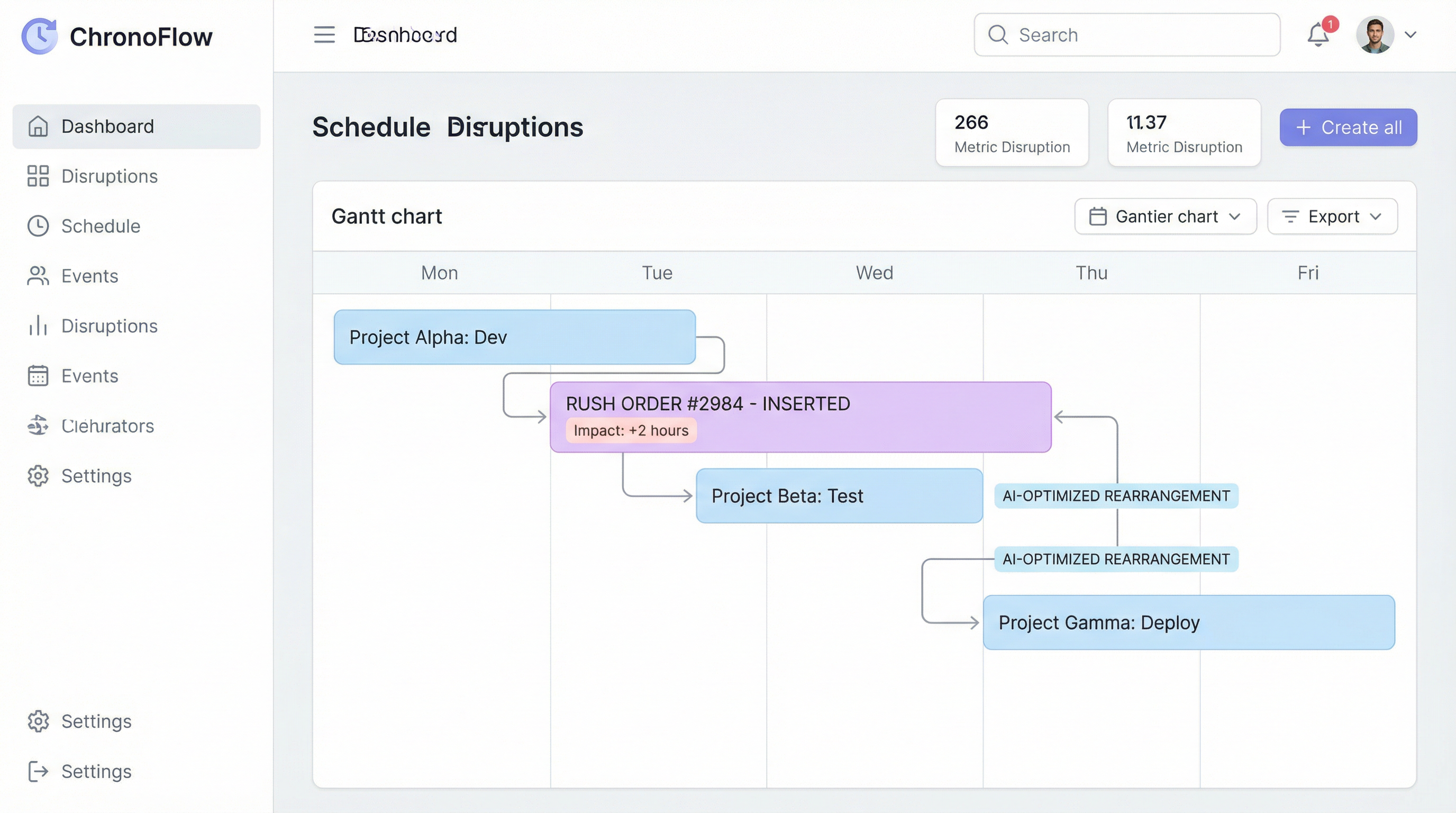

SCHEDULE DISRUPTIONS: Adapt in Real-Time

"Urgent rush order arrives. Planner spends all day manually reshuffling Excel schedule."

Before (Manual)

- • Export schedule to Excel

- • Manual drag-and-drop guessing

- • Call supervisors to check status

- • Publish outdated plan

Result: Chaos & sub-optimal plan

With ProssimaAI

- Dynamic AI Rescheduling

- Instant Impact Analysis

- Scenario Simulation (What-if)

Result: Optimal schedule in seconds

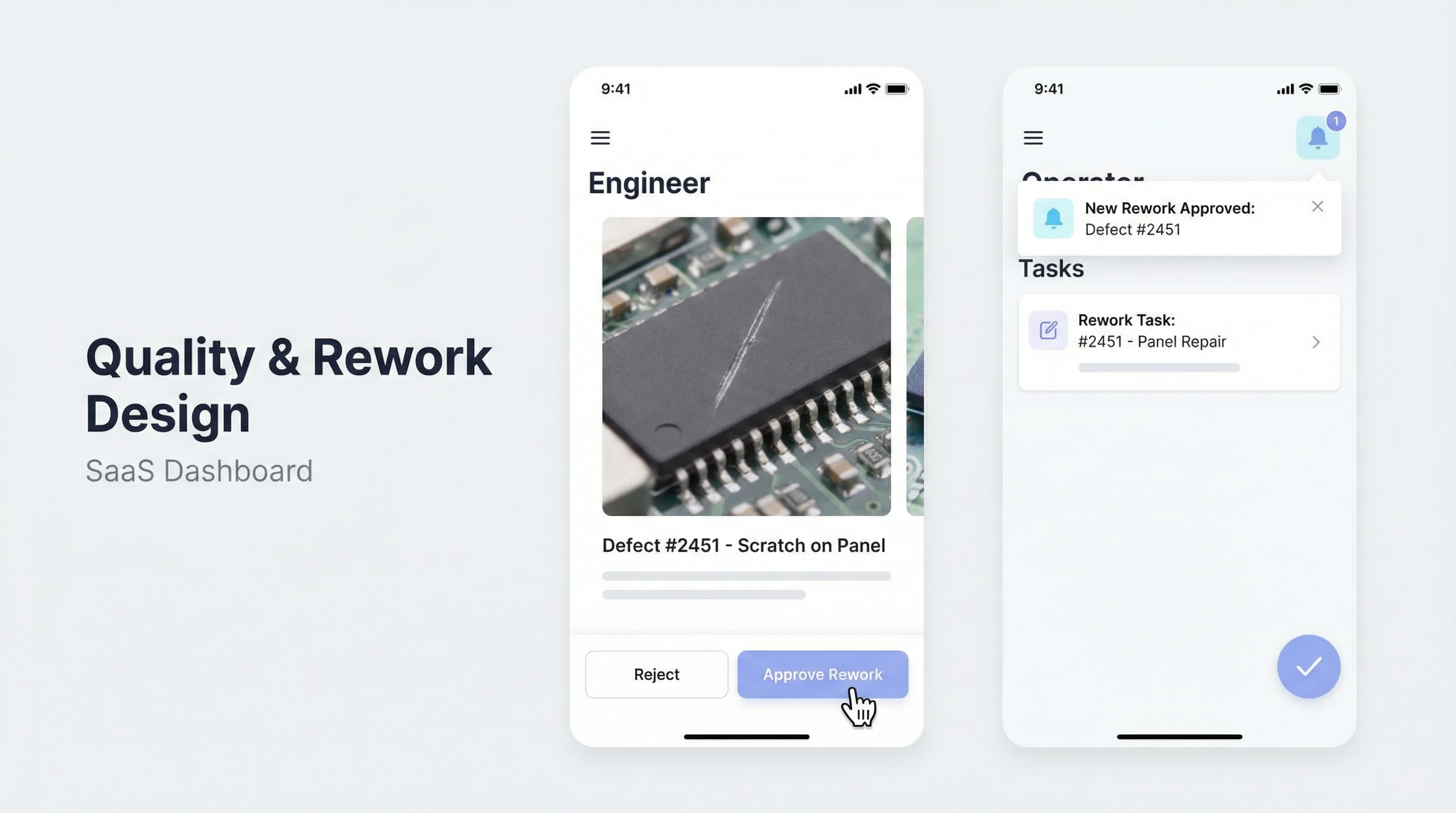

QUALITY & REWORK: Smart Decisions

"Batch fails inspection. Production waits for engineering decision on rework vs scrap."

Before (Manual)

- • Paper NCR raised

- • Engineer busy, form sits on desk

- • Inventory quarantined for days

- • Production stalled

Result: WIP buildup & delays

With ProssimaAI

- Digital NCR Workflow

- AI-recommended disposition

- Instant routing to engineer

Result: Decisions in minutes

WORK ORDER TRACKING: Real-Time Status

"Sales asks 'When will order X be ready?' Production has to walk the floor to find out."

Before (Manual)

- • Sales emails production

- • Supervisor walks to machine

- • Checks paper job card

- • Replies 4 hours later

Result: Communication lag

With ProssimaAI

- Digital Job Cards on tablets

- Live status updates to ERP

- Sales portal visibility

Result: Instant answers for customers

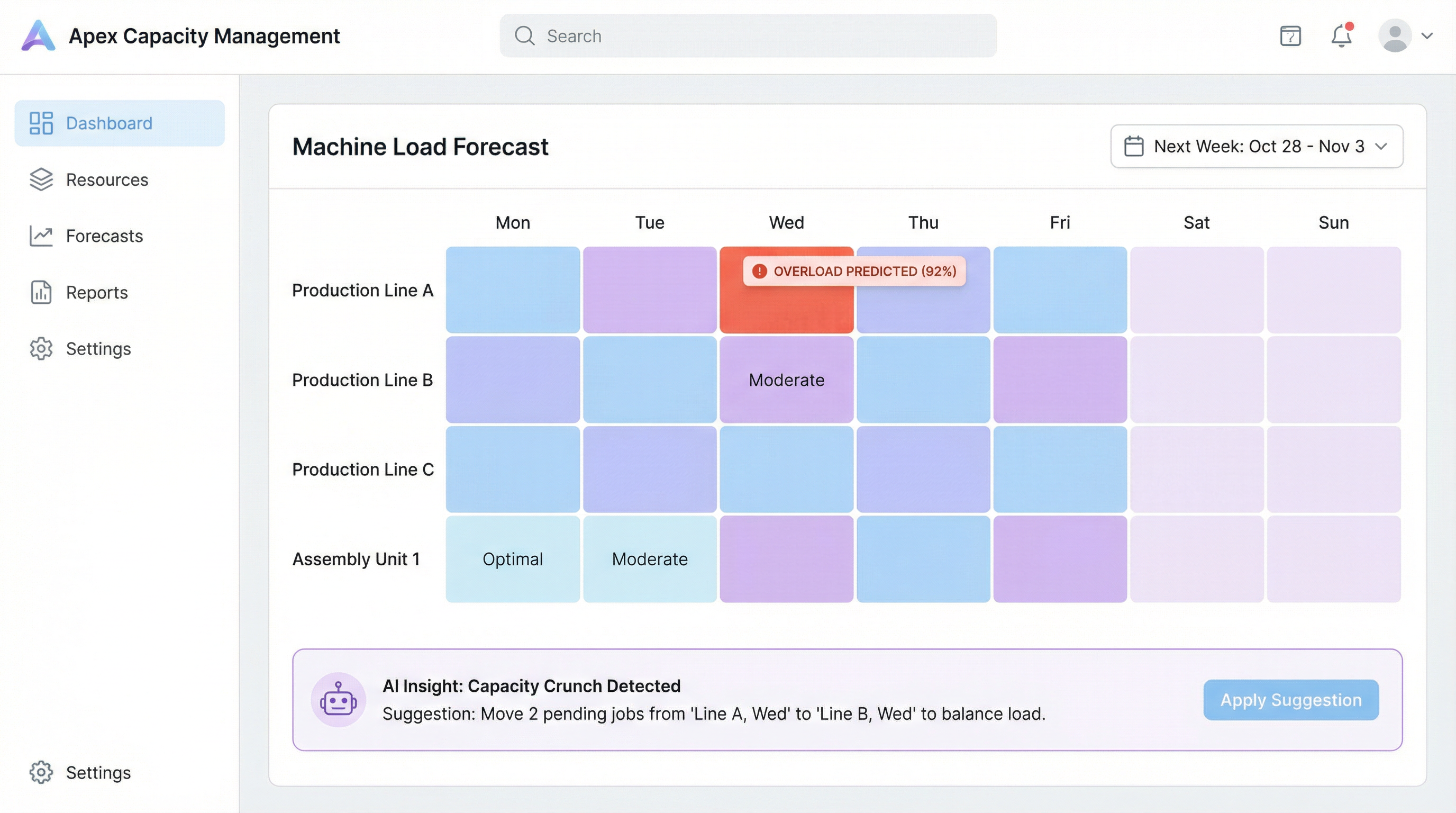

CAPACITY MANAGEMENT: Spot Bottlenecks

"One machine is overloaded while others are idle. You don't see it until end of week."

Before (Manual)

- • Weekly capacity review

- • Bottleneck discovered too late

- • Overtime costs incurred

- • Deliveries missed

Result: Inefficient utilization

With ProssimaAI

- Live Load Balancing

- Future Bottleneck Prediction

- Shift Optimization suggestions

Result: Balanced line & lower costs

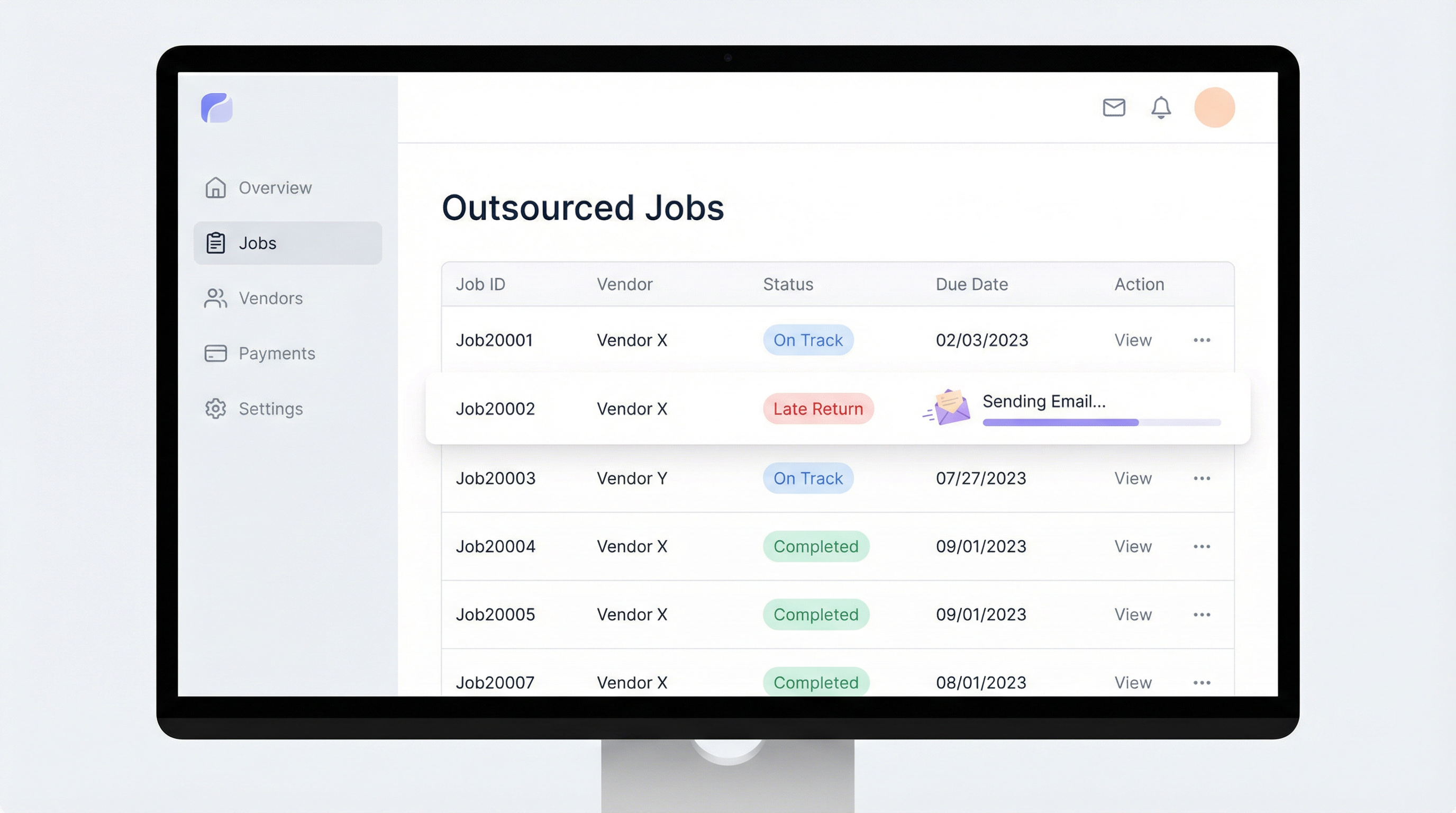

SUBCONTRACTING: Track Outsourcing

"Parts sent to job worker. No idea if they started or when they will return."

Before (Manual)

- • Manual challan creation

- • Phone calls to vendor for status

- • Delayed return delays assembly

- • Inventory mismatch common

Result: Black hole in supply chain

With ProssimaAI

- Vendor Portal for updates

- Auto-aging alerts for WIP

- Reconciliation of material sent/received

Result: Full visibility of external WIP